Services

Parylene Coating

Process

Description of Parylene: Parylene is the trade name for a variety of polyxylylene polymers marketed by several providers. Parylene N is a polymer manufactured from di-p-xylylene, a dimer synthesized from p-xylylene. Di-p-xylylene, more properly known as paracyclophane, is made from p-xylylene in several steps involving bromination, amination and elimination.

Parylene is a common generic name for a unique series of polymers based on paraxylene. The three most common types of parylene are referred to as: Parylene N, Parylene C, and Parylene D. In actual usage, Parylene C is the greatly predominant type of parylene used for almost all types of applications and as such is usually the type of material associated as “Parylene.” The basis for the parylene family is the polyp-xylene monomer which comprises Parylene N. Parylene C and D are created by the substitution of a single chlorine molecule (C) or two (double) chlorine molecules (D). See Figure 1.

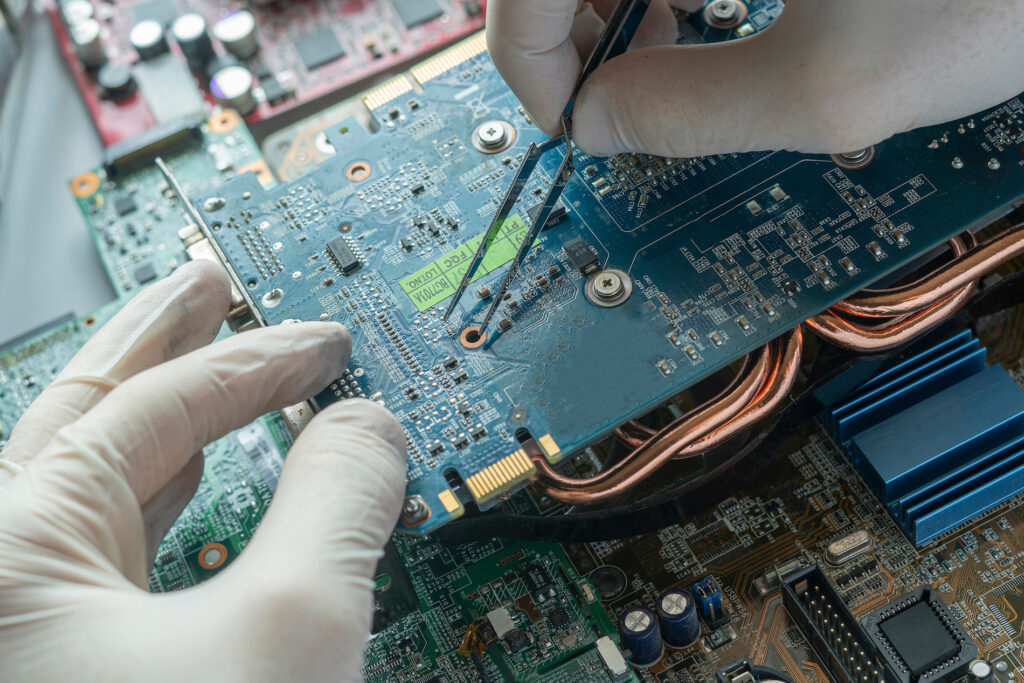

There are a number of derivatives and isomers of Parylene, but only a few are used commercially, e.g., Parylene N, Parylene C and Parylene D. This article discusses the molecule which isn’t substituted, which produces Parylene N. Heating paracyclophane in a partial vacuum gives rise to a diradical species which polymerizes when deposited on a surface. Until the “monomer” comes into contact with a surface it is in a gaseous phase and can access the entire exposed surface. It has a variety of uses. In electronics, chemical vapor deposition at low pressure onto circuit boards produces a thin, even conformal polymer coating. Parylene coating has very high electrical resistivity and resists moisture penetration. It is used as a dielectric in certain high-performance capacitors for precision measurement. It has uses in preserving archival paper.

Characteristics and advantages

- Hydrophobic, chemically resistant coating with good barrier for inorganic and organic media, strong acids, caustic solutions, gases and water vapor.

- Outstanding electrical isolation with high tension strain and low dielectric constant

- A biostable, biocompatible coating, FDA permission

- micropore and pin get-free starting from 0.2 µm layer thickness,

- Thin and transparent coating with high gap freedom of movement, suitably for complex arranged substrates also on edges.

- Coating without temperature load of the substrates, coating takes place at ambient temperature in the vacuum.

- Highly corrosion resistant.

- Completely homogeneous surface.

- Thermally stable up to 220 °C, mechanically stable from -200 °C to +150 °C.

- Low mechanical stresses.

- Resistant to friction.

- Very low permeability to gases.

- High electrical impedance.

Typical applications

- Dielectric coating (e.g. Cores/coils).

- Hydrophobic coating (e.g. biomedical hoses).

- Barrier layers (e.g. for filter, diaphragms, valves).

- Microwave electronics.

- Sensors in rough environment.

- Electronics for space travel and military.

- Corrosion protection for metallic surfaces.

- Reinforcement of micro-structures.

- Abrasion protection.

- Protection of plastic, rubber, etc. from harmful environmental conditions.

- Reduction of friction (e.g. For guiding catheters, also acupuncture needles).

- Dissolving deuterated polyethylene for making nuclear targets.

Additional Advantages / Benefits

- MIL-I-46058C, Type XY approved

- FDA approved — USP XXII, Class VI bio-compatibility rating

- UL listed

- Completely pin-hole free barrier coating

- Fully conformal on any type of surface material or design

- Inert transparent polymer

- Meets NBC requirements (AR70 / AFR80-38 / Navinst 3400.2)

- Barrier to oxygen, moisture, chemicals, solvents, and carbon dioxide

- Thermal mechanically stable between -200ºC and 150ºC

- Extremely high dielectric 5,000 volts per 0.001″ minimum

- Excellent adhesion properties

- Low stress coating that does not form sites prone to crack initiation

- Low / minimal impact on package cooling

- Hydrophobic

- Barrier to ionic and moisture species

- Chemical and fungal resistance

- Non-contaminating coating and coating process — no solvents, catalysts or other by-products are introduced during coating

- Entire process is accomplished at room temperature, alleviating temperature stress on parts

- Particle encapsulation / immobilization

- No outgassing (NASA approved)

- High reliability – Suitable for military or commercial applications

- Light weight – compared to other coatings

- Stress-free coatings – Sensitive circuitry unchanged by coating

- Low coefficient of friction – Use as a dry film lubricant

- Transparency – Thin films can be of optical quality

- Outgassing – Virtually none

- Outstanding barrier – Very low permeability to moisture and gases

- Fungus and bacteria resistance – Excellent

- Mechanical – High tensile and yield strength

- Radiation resistance – Suitable for space applications

The parylenes are formed by the pyrolysis of a di-p-xylene (dimer) in a vacuum environment which is then deposited on a cooler (i.e. room temperature) substrate under continuous vacuum. Vapor phase deposition of the parylene polymer allows it to be formed as a structurally continuous film which is truly conformal to the design and structure of the substrate upon which it is being deposited. Parylene can be effectively deposited with excellent accuracy in the thickness range of 0.1 mils to over 2 mils.

Figure 1

Parylene C

The most widely used dimer, providing a useful combination of properties, plus a very low permeability to moisture, chemicals, and other corrosive gases.

Parylene N

Provides high dielectric strength and a dielectric constant that does not vary with changes in frequency. Best selection where greater coating protection is required.

Parylene D

Maintains its physical strength and electrical properties at higher temperatures.

![DQS-MED_ISO9001-2015_blue_A3-[Converted] DQS-MED_ISO9001-2015_blue_A3-[Converted]](https://paryleneengineering.com/wp-content/uploads/elementor/thumbs/DQS-MED_ISO9001-2015_blue_A3-Converted-q80axhh9ng6w3tn4cav5qn6ln81imoxnftzvm5g2k8.png)