|

Parylene

is a thin film polymer coating that delivers unsurpassed barrier

protection in a wide range of products and applications in industries

ranging from automotive to semi-conductor and electronics.

But, it is

perhaps in the medical device industry where parylene sees it’s

most diverse and widespread use. It offers a level of protection

to critical components that is unequaled by any other coating.

No other coating can boast similar properties. Parylene is

biocompatible, pinhole-free, extremely thin, and protects

against the effects of fluids and solvents.

|

|

The benefits of parylene as a solution for your critical products are

clear:

|

- Biocompatible-biologically stable and chemically inert

- Non-toxic

- Conforms precisely to substrate contours

- Provides excellent dry film lubricity

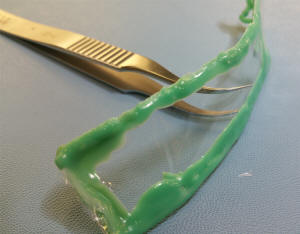

- Medical devices and instruments (syringes, catheters,

implants)

- Electronic components (pcb, motors, assemblies)

- Aerospace and Aviation electronics and other components

- LEDS (Displays, SMD, circuit arrays)

- MEMS

- Nanotech

- Semiconductor products (probes, membranes, other)

- Silicone gaskets, seals, O-rings

- Rare Earth Magnets

- Glass

- Barrier protection against chemical, moisture and bodily fluids

- Ultra-thin with deep crevice penetration

- Unparalleled dielectric properties

- Adds minimal weight and volume

- Withstands sterilization (E-beam,

Gamma, EtO, Autoclave, Etc.)

|

|

Parylene Engineering provides the most extensive line of

premiere parylene products, all of which are far superior in purity.

Parylene Engineering's dimer is at 99.9% purity while others are at 93%. Our most widely

used parylene dimers, C and N, are in full compliance with ISO standards

as related to implants, cytotoxicity, tissue sensitization and

compatibility, among others. We have clean room facilities in our

coating centers in the US and in 10 locations around the world to serve

you. Our products comply with the European Union’s Restriction on Use of

Hazardous Substances (RoHS) and meet requirements for USP Class VI. In

addition, Parylene Conformal Coating maintains an FDA Drug Master File

which, upon request, can be referenced by our customers.

Parylene adheres to virtually any type of surface material –

invaluable in coating the wide selection of substrates encountered in

modern medical devices: ceramics, plastics, silicone rubber, elastomers,

metal or glass.

|

|

|

Typical products and components coated by Parylene

Engineering include: |

-

Coronary

stents

- Probes, electrodes and circuits/pcb

- Needles

- Implantables

- Catheters and cannulae

- Mandrels

- Hearing aids

- Medicine bottles

|

|