|

What is Parylene?

Parylene is the

generic name for the

poly-para-xylylenes.

These materials form

linear,

highly-crystalline

polymers but can be

usefully produced

only as coatings and

films. The most

commonly used is

Parylene C, the

mono-chloro

substituted

compound. Parylene

N, the

un-substituted

compound, has better

high-frequency

dielectric

properties, better

penetrating power

for coating the bore

of very small

diameter tubes, and

is often preferred

in medical

applications.

Parylene D, the

di-chloro-substituted

compound, has better

high temperature

endurance.

The Parylene Coating

Process

The Parylene process

is unique in coating

technology and is

best described as a

vapor deposition

polymerization. It

is carried out under

vacuum and requires

specialized

equipment.

|

|

|

|

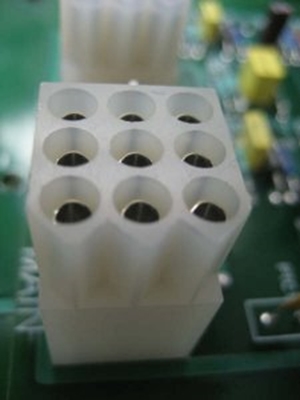

Parylene is applied

at room temperature

with specialized

vacuum deposition

equipment that

permits control of

coating rate and

thickness. The

deposition process

takes place at the

molecular level as

the chemical, in

dimer form, is

converted under

vacuum and heat to

dimeric gas;

pyrolized to cleave

the dimer; and

finally deposited as

a clear polymer

film.

The material is

applied at .0002-in

per hr. Coating

thicknesses from

.100 to 76 microns

can be applied in a

single operation.

Typical coating

thickness for

circuit boards is

.00 I-in.

|

|

|

Parylene General

Properties Benefits

-

MIL-I-46058C,

Type XY approved

-

FDA approved

- USP XXII,

Class VI

bio-compatibility

rating

-

UL listed

-

Completely

pin-hole free

barrier coating

-

Fully conformal

on any type of

surface material

or design

-

Inert

transparent

polymer

-

Meets NBC

requirements

(ARlO / AFR80-38

/ Navinst

3400.2)

-

Barrier to

oxygen,

moisture,

chemicals,

solvents, and

carbon dioxide

-

Thermal

mechanically

stable between

-200°C and 150°C

-

Extremely high

dielectric 5,000

volts per 0.001"

minimum

-

Excellent

adhesion

properties

-

Low stress

coating that

does not form

sites prone to

crack initiation

-

Low / minimal

impact on

package cooling

-

Hydrophobic

-

Barrier to ionic

and moisture

species

-

Chemical and

fungal

resistance

-

Non-contaminating

coating and

coating process

--no solvents,

catalysts or

other

by-products are

introduced

during coating

-

Entire process

is accomplished

|

|